Description

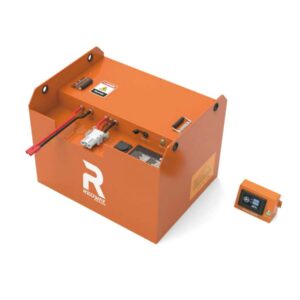

Introducing the 48V 200Ah LiFePO4 Forklift Battery, a powerful energy solution from OEM Lithium Batteries, a leading China manufacturer specializing in OEM and ODM services. This high-capacity lithium iron phosphate (LiFePO4) battery is designed for heavy-duty industrial applications, making it ideal for wholesale buyers looking to enhance their material handling operations.

- High Energy Output: With a nominal capacity of 200Ah and an energy storage of approximately 9.6 kWh, this battery delivers reliable power for extended forklift operations, ensuring uninterrupted productivity throughout long shifts.

- Superior Discharge Performance: The battery offers a continuous discharge current of 600A and a peak discharge current of 800A for short bursts, providing optimal performance during demanding tasks in various industrial settings.

- Long Cycle Life: Engineered for over 3,000 cycles at 100% Depth of Discharge (DoD), this battery provides exceptional longevity, significantly reducing the total cost of ownership compared to traditional lead-acid batteries.

- Advanced Safety Features: Equipped with a sophisticated Battery Management System (BMS), this battery includes protections against overcharging, over-discharging, overcurrent, and overheating, ensuring safe operation in all environments.

- Flexible Communication & Monitoring: Supports RS485, CAN-bus, and 4G remote monitoring capabilities for real-time performance tracking and efficient fleet management, allowing businesses to optimize their operations effectively.

Product Description

The 48V 200Ah LiFePO4 Forklift Battery is meticulously engineered to provide superior power and reliability for material handling operations:

- Energy Output:

- Delivers a nominal energy output of approximately 9.6 kWh.

- Ensures long-lasting performance in demanding environments such as warehouses, logistics centers, and manufacturing facilities.

- Design and Durability:

- Designed with OEM, ODM, and wholesale buyers in mind.

- Features an IP65 rating for resistance to dust and water ingress.

- Robust metal shell provides additional protection in challenging industrial settings.

- Battery Management System (BMS):

- The advanced BMS continuously monitors critical parameters such as state of charge (SOC), voltage, current, and temperature.

- Provides real-time alerts and protections against overcharge, overdischarge, overcurrent, and low-voltage conditions.

- Cycle Life and Maintenance:

- Boasts a cycle life exceeding 3,000 cycles at 100% DOD.

- Guarantees longevity and minimal maintenance requirements.

- Reduces downtime compared to traditional lead-acid batteries.

- Customization Options:

- For OEM/ODM clients, extensive customization options are available including different voltage configurations (48V), capacity adjustments (customizable), and various connector types.

- Flexible delivery terms (FOB, EXW, CIF) ensure that your orders arrive promptly within 25 days.

Choosing the 48V 200Ah LiFePO4 Forklift Battery means investing in an eco-friendly power solution that enhances your material handling operations while minimizing long-term costs. As a trusted supplier from China, OEM Lithium Batteries is committed to providing high-quality solutions tailored to your business requirements.

Contact us today to discuss how we can meet your specific needs with our innovative battery technology! Experience the advantages of working with a reputable Chinese manufacturer dedicated to innovation and customer satisfaction. Whether you require bulk orders or tailored solutions, we are here to support your business with our expertise in LiFePO4 batteries.

48V 200Ah LiFePO4 Forklift Battery Specifications

What are 48V 200Ah LiFePO4 forklift battery specifications?

A 48V 200Ah LiFePO4 forklift battery delivers 9.6 kWh energy capacity, with a lifespan of 3,000 to 5,000 cycles, superior thermal stability, and a built-in Battery Management System (BMS) for safety.

What are the key performance metrics for 48V 200Ah forklift batteries?

Key performance metrics include 95% energy efficiency, 3,000+ charge cycles, 80% depth of discharge, and consistent voltage maintenance under heavy loads.

How does temperature affect lithium forklift battery lifespan?

Higher temperatures shorten lithium battery lifespan, while temperatures between 0°C to 45°C ensure optimal performance and prolonged cycle life.

What is the typical charging time for 48V 200Ah lithium batteries?

Charging a 48V 200Ah LiFePO4 battery takes 4 to 5 hours with a fast charger, ensuring reduced downtime and efficient energy use.

How do lithium forklift batteries compare to lead-acid in efficiency?

LiFePO4 batteries offer 95% energy efficiency, faster charging, and longer lifespan, outperforming lead-acid batteries with only 70-80% efficiency.

What safety standards apply to long-lasting lithium forklift batteries?

LiFePO4 batteries meet UL, CE, IEC, and UN38.3 safety standards, ensuring protection against overcharging, overheating, and short circuits.

LiFePO4 Forklift Battery Benefits

Why choose LiFePO4 for electric forklifts?

LiFePO4 batteries provide longer lifespan, faster charging, lower maintenance, and higher energy efficiency, making them ideal for electric forklifts.

How do LiFePO4 batteries enhance forklift safety?

LiFePO4 batteries include a Battery Management System (BMS) that prevents overcharging, overheating, and short-circuits, ensuring forklift safety.

What is LiFePO4 lifespan in industrial use?

LiFePO4 batteries last 3,000 to 5,000 cycles in industrial environments, significantly longer than lead-acid alternatives, reducing replacement costs.

How fast do LiFePO4 batteries charge vs alternatives?

LiFePO4 batteries charge 2-3 times faster than lead-acid batteries, taking 4-5 hours compared to 8-10 hours for lead-acid.

Are LiFePO4 forklift batteries cost-effective long-term?

Yes, LiFePO4 batteries reduce overall ownership costs by extending lifespan, minimizing maintenance, and lowering energy consumption.

What maintenance do LiFePO4 forklift batteries require?

Minimal maintenance is required, such as keeping terminals clean, monitoring charge cycles, and ensuring optimal temperature for performance.

China OEM LiFePO4 Battery Manufacturing

How to customize OEM LiFePO4 forklift batteries in China?

Customization options include adjusting voltage, capacity, size, and integrating advanced BMS systems to meet specific forklift application needs.

Why choose China OEM for cost-effective LiFePO4 forklift batteries?

China OEMs offer competitive pricing, advanced manufacturing technologies, quality certifications, and faster production cycles for LiFePO4 batteries.

What are the key steps in 48V 200Ah forklift battery production?

Key steps include cell selection, BMS integration, module assembly, testing, and quality assurance to meet international safety standards.

How to ensure quality control for custom OEM forklift batteries?

Quality control includes rigorous performance testing, certification checks, thermal stability assessments, and compliance with safety standards.

What certifications are required for China-made forklift batteries?

Certifications include UL, CE, IEC, UN38.3, and ISO 9001, ensuring compliance with global safety and quality standards.

What are cost advantages of China-based OEM battery manufacturing?

China OEMs provide cost advantages through economies of scale, lower labor costs, and streamlined production processes, ensuring competitive pricing.

LiFePO4 Forklift Battery Installation and Maintenance

How to install 48V 200Ah LiFePO4 batteries in forklifts?

Follow manufacturer guidelines, ensure secure terminal connections, and verify proper voltage alignment to prevent installation errors.

What tools are needed for LiFePO4 forklift battery installation?

Essential tools include insulated gloves, voltage meters, torque wrenches, and protective gear for safe installation procedures.

How to ensure safety during OEM battery installation procedures?

Use appropriate insulation, verify voltage compatibility, follow installation manuals, and conduct pre-operation tests to ensure safety.

What are key steps for installing LiFePO4 forklift batteries?

Key steps include battery positioning, terminal connection, voltage alignment, BMS calibration, and final performance testing.

How to test battery performance post-installation effectively?

Test by monitoring voltage, discharge rate, temperature control, and overall system stability during initial operation.

What maintenance practices extend LiFePO4 battery lifespan post-installation?

Regular inspections, charge cycle monitoring, terminal cleaning, and maintaining optimal operating temperatures extend battery lifespan.

Warehouse and Industrial Applications

LiFePO4 batteries suitable for industrial forklift applications?

Yes, LiFePO4 batteries are ideal for high-capacity, continuous-operation industrial forklifts due to their reliability and long lifespan.

Why choose LiFePO4 for warehouse energy storage?

LiFePO4 batteries provide stable voltage, fast charging, and long cycle life, making them ideal for energy storage in warehouse applications.

How to ensure safety in warehouse LiFePO4 systems?

Ensure safety by using BMS, maintaining optimal temperature, regular inspections, and adhering to UL and CE safety standards.

How do LiFePO4 batteries optimize warehouse operations?

LiFePO4 batteries reduce downtime, improve energy efficiency, and enhance forklift operational reliability in warehouse environments.

Which forklift models are compatible with China OEM batteries?

Most electric forklift models, including CAT, Toyota, and Hyster, are compatible with customized China OEM 48V LiFePO4 batteries.

What innovations improve 48V LiFePO4 battery efficiency?

Innovations include advanced BMS systems, fast-charging technology, and improved thermal management for enhanced battery performance.

Cost and Longevity Considerations

What defines a cost-effective 48V 200Ah LiFePO4 battery?

Cost-effectiveness is defined by long cycle life, reduced maintenance, high efficiency, and minimal replacement frequency, lowering total ownership costs.

How long is the design process for custom forklift batteries?

The design process for custom forklift batteries typically takes 2 to 4 weeks, depending on specifications and complexity.

What maintenance practices optimize lithium forklift battery longevity?

To optimize longevity, maintain appropriate charge levels, avoid deep discharges, and monitor temperature conditions during use.

How long is the lifespan of 48V 200Ah lithium forklift batteries?

48V 200Ah LiFePO4 batteries last 3,000 to 5,000 cycles, equivalent to 8-10 years, depending on usage conditions.

What materials optimize 48V 200Ah forklift battery performance?

High-quality lithium iron phosphate cells, advanced BMS systems, and efficient thermal management materials optimize battery performance.

What are cost advantages of China-based OEM battery manufacturing?

China-based OEMs offer cost advantages through mass production, lower raw material costs, and efficient labor, reducing overall battery prices.