Description

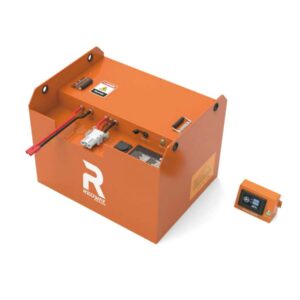

Introducing the 48V 550Ah LiFePO4 Forklift Battery, a high-capacity energy solution specifically designed for demanding material handling applications. As a premier OEM manufacturer in China, we provide advanced lithium iron phosphate (LiFePO4) batteries that deliver exceptional performance and reliability. This product is ideal for OEM, ODM, and wholesale buyers looking to enhance their forklift operations.

Key Features

- High Capacity: With a nominal capacity of 550Ah and an energy output of approximately 28.6 kWh, this battery ensures extended operational hours for forklifts, maximizing productivity during shifts.

- Long Cycle Life: Designed to last over 6,000 cycles at 80% depth of discharge (DoD), this battery significantly reduces maintenance costs and replacement frequency compared to traditional lead-acid batteries.

- Powerful Performance: Capable of delivering a continuous discharge current of 400A, with peak discharge currents reaching up to 800A for short bursts, making it suitable for heavy-duty applications.

- Robust Construction: Built with a durable metal casing and rated IP67, this battery is dust-tight and water-resistant, ensuring reliable performance in harsh environments.

- Advanced Battery Management System (BMS): Features a smart BMS that protects against overcharging, short circuits, and overheating while continuously monitoring voltage, current, and temperature for optimal safety and efficiency.

Product Description

The 48V 550Ah LiFePO4 Forklift Battery is meticulously engineered to provide dependable power for modern material handling operations. Utilizing cutting-edge LiFePO4 technology, this battery delivers a nominal voltage of 48V, ensuring exceptional energy density and efficiency. Its dimensions of 950 x 600 x 450 mm and weight of approximately 280 kg make it compatible with various forklift models without compromising performance.

- This battery operates effectively across a wide temperature range from -20°C to 60°C, making it ideal for both indoor and outdoor applications. The natural cooling system enhances reliability by maintaining optimal performance without the need for additional cooling devices.

- With a maximum continuous charge current of 250A and a peak discharge current of 800A, this battery supports high-demand applications while prioritizing safety through its advanced BMS. The BMS continuously monitors critical parameters such as state of charge (SOC), voltage, current, cell temperature, and voltage imbalance to ensure safe operation throughout its lifespan.

Investing in the 48V 550Ah LiFePO4 Forklift Battery not only provides a reliable power source but also contributes to sustainability efforts with its eco-friendly design. The long lifespan minimizes the need for frequent replacements, ultimately lowering your total cost of ownership.

- For OEM/ODM clients, this battery is available with flexible customization options including different voltage configurations (48V), capacity adjustments (customizable), and various connector types. Our delivery terms are adaptable (FOB, EXW, CIF) to ensure timely arrival within 25 days.

Choose the 48V 550Ah LiFePO4 Forklift Battery for an efficient, powerful, and environmentally friendly solution tailored to your material handling needs. As a trusted manufacturer in China, OEM Lithium Batteries is committed to providing high-quality products that cater to B2B requirements while maintaining competitive pricing and exceptional service. Contact us today to discuss how we can meet your specific needs with our innovative battery technology!

48V 550Ah LiFePO4 Battery Specifications

What are key specifications of 48V 550Ah LiFePO4 forklift batteries?

The key specifications of 48V 550Ah LiFePO4 forklift batteries include a nominal voltage of 48V, 550Ah capacity, and a battery management system (BMS) for safety. They offer a long cycle life of 3,000-5,000 charge cycles and a wide operating temperature range from -20°C to 60°C. These batteries also have overcharge and temperature protection features for efficient operation.

What applications use 48V 550Ah LiFePO4 forklift batteries?

48V 550Ah LiFePO4 forklift batteries are commonly used in high-demand material handling applications like warehousing, logistics, and distribution centers. They power electric forklifts, automated guided vehicles (AGVs), and other industrial equipment that require long operational hours and minimal downtime.

How do LiFePO4 batteries compare to lead-acid in forklifts?

LiFePO4 batteries outperform lead-acid by offering longer lifespan, faster charging, and lower maintenance. They are lighter, more energy-efficient, and provide consistent power, making them ideal for forklifts and material handling equipment. Unlike lead-acid, they don’t require water refilling or equalization charging.

What is the lifespan of 48V 550Ah LiFePO4 forklift batteries?

The lifespan of 48V 550Ah LiFePO4 forklift batteries is typically 3,000 to 5,000 charge cycles, which translates to 8 to 10 years under normal operating conditions. Proper care, such as avoiding deep discharge and managing temperature, can help maximize battery life.

How long does charging take for 48V 550Ah LiFePO4 batteries?

Charging time for 48V 550Ah LiFePO4 batteries typically ranges from 3 to 6 hours depending on the charger’s output and the battery’s current charge level. Fast-charging solutions can reduce charging time, ensuring minimal downtime for forklifts and other material handling equipment.

What maintenance is required for LiFePO4 forklift batteries?

LiFePO4 forklift batteries require minimal maintenance. Key tasks include monitoring charging cycles, cleaning terminals, and ensuring proper ventilation. The Battery Management System (BMS) should be regularly checked, but unlike lead-acid batteries, LiFePO4 batteries do not need water refilling or frequent equalization charging.

China OEM LiFePO4 Forklift Batteries

Top criteria for selecting China OEM LiFePO4 forklift battery manufacturers?

When selecting China OEM LiFePO4 forklift battery manufacturers, consider product quality, certifications (UL, CE, UN38.3), customization options, price competitiveness, and warranty terms. Additionally, assess their manufacturing capabilities, delivery times, and customer service to ensure long-term reliability and support.

How do China OEM LiFePO4 batteries enhance forklift performance?

China OEM LiFePO4 batteries enhance forklift performance by providing higher energy density, longer runtime, and faster charging. These batteries offer consistent power delivery, reduce downtime, and require less maintenance than traditional lead-acid batteries, boosting overall productivity and cost efficiency in material handling operations.

What certifications ensure quality in China LiFePO4 forklift batteries?

Quality certifications for China LiFePO4 forklift batteries include UL 1642, CE, UN38.3, IEC 62619, and ISO 9001. These certifications guarantee compliance with international safety, environmental, and performance standards, ensuring that the batteries meet safety, reliability, and durability requirements for industrial use.

How cost-effective are China OEM LiFePO4 batteries for forklifts?

China OEM LiFePO4 batteries are cost-effective due to economies of scale, competitive manufacturing costs, and high production volumes. While the initial cost may be higher than lead-acid, the long-term savings on maintenance, downtime, and energy efficiency make LiFePO4 batteries a more cost-effective solution for forklift fleets.

What innovations drive China’s LiFePO4 forklift battery market growth?

Innovations in China’s LiFePO4 forklift battery market include advanced Battery Management Systems (BMS), higher energy density cells, faster-charging technology, and improved thermal management. Manufacturers are also focusing on sustainability, recycling initiatives, and integrating smart technology for real-time monitoring and maintenance.

How do China OEMs handle LiFePO4 battery customization for forklifts?

China OEMs offer customization for LiFePO4 forklift batteries by adjusting capacity, voltage, and battery dimensions to meet specific forklift requirements. They also tailor features like charging speed, battery management systems (BMS), and pack configurations to optimize performance in various industrial environments.

LiFePO4 Advantages in Forklifts

What are key benefits of LiFePO4 in forklifts?

LiFePO4 batteries provide key benefits for forklifts, including longer lifespan, faster charging, lower maintenance, and higher efficiency. They are lightweight, safe, and capable of handling high discharge rates, making them ideal for demanding forklift operations that require extended runtimes and reduced downtime.

How do LiFePO4 batteries outperform lead-acid alternatives?

LiFePO4 batteries outperform lead-acid by offering longer lifespan (3,000-5,000 cycles vs. 500-1,000), faster charging, and higher energy efficiency. They are also lighter, require less maintenance, and provide consistent power without the need for water refilling or equalization charging.

What industries prioritize high-capacity forklift batteries?

Industries such as warehousing, logistics, automotive, and manufacturing prioritize high-capacity forklift batteries. These industries rely on high-capacity batteries to power electric forklifts, AGVs, and other material handling equipment, enabling long shifts, greater productivity, and reduced operational costs.

What maintenance requirements do LiFePO4 forklift batteries have?

LiFePO4 forklift batteries have minimal maintenance compared to lead-acid. Key tasks include monitoring charge cycles, cleaning terminals, and ensuring proper ventilation. The Battery Management System (BMS) should be checked regularly to ensure safety and performance. No need for water refilling or equalization charging.

How do LiFePO4 batteries impact operational cost efficiency?

LiFePO4 batteries lower operational costs by offering longer lifespan, lower maintenance costs, and higher energy efficiency. Their faster charging reduces downtime, while reduced energy consumption and longer run times allow for higher productivity and lower total cost of ownership in material handling operations.

What innovations drive LiFePO4 adoption in material handling?

Innovations driving LiFePO4 adoption in material handling include advanced BMS, fast-charging technology, integration of IoT for monitoring, and improved battery life management. These innovations provide greater safety, real-time performance tracking, and sustainability, making LiFePO4 the preferred choice for modern forklift fleets.

Lithium vs Lead-Acid Forklift Batteries

What defines a 550Ah lithium forklift battery’s lifespan?

A 550Ah lithium forklift battery’s lifespan is typically 3,000 to 5,000 charge cycles, translating to 8 to 10 years under normal operating conditions. Proper maintenance, avoiding deep discharges, and maintaining optimal temperatures can maximize the battery’s life.

How do lithium batteries compare to lead-acid in forklifts?

Lithium batteries outperform lead-acid in forklifts by offering longer lifespan, faster charging, higher energy efficiency, and lower maintenance. Lithium batteries also provide consistent performance, are lighter, and do not require water refilling or equalization charging, making them more cost-effective in the long run.

Applications for 550Ah lithium forklift batteries?

550Ah lithium forklift batteries are commonly used in high-demand material handling applications, including electric forklifts, automated guided vehicles (AGVs), and material handling systems in warehouses, distribution centers, and logistics operations. They offer extended run times and faster recharging for efficient operations.

Maintenance requirements for long-lasting lithium forklift batteries?

Lithium forklift batteries require minimal maintenance. To ensure longevity, avoid deep discharge and overcharging. Clean terminals regularly, and ensure the Battery Management System (BMS) is working correctly. Lithium batteries don’t require water refilling or equalization charging, reducing overall maintenance time.

Cost-benefit analysis of 550Ah lithium vs traditional batteries?

550Ah lithium forklift batteries have a higher upfront cost than traditional lead-acid batteries but provide significant long-term savings. They offer longer lifespan, faster charging, lower maintenance costs, and greater efficiency, making them more cost-effective over time. They also reduce downtime and energy consumption.

Industry trends in lithium battery adoption for material handling?

The industry trend shows increased adoption of lithium batteries in material handling due to their longer lifespan, faster charging, low maintenance, and high efficiency. This trend is driven by the demand for sustainability, improved operational efficiency, and cost savings in industries such as logistics, warehousing, and manufacturing.